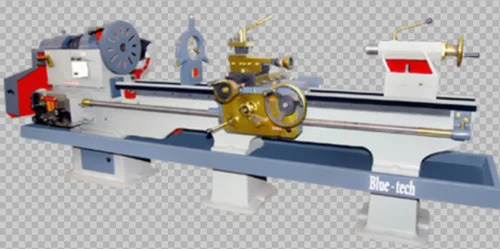

Conventional Lathe Machine

Product Details:

- Product Type Conventional Lathe Machine

- Material Cast Iron Structure

- Cutting Thickness Up to 8 mm (varies by material) Millimeter (mm)

- Cutting Speed 35 1800 RPM RPM

- Automatic Grade Manual

- Control System Manual

- Max. Swing Diameter 410 mm Millimeter (mm)

- Click to View more

Conventional Lathe Machine Price And Quantity

- 1 Unit

- 125000 INR

Conventional Lathe Machine Product Specifications

- 2650 x 900 x 1250 mm Millimeter (mm)

- Cast Iron Structure

- Manual

- Other

- 410 mm Millimeter (mm)

- Manual

- 1200 kg (Approx) Kilograms (kg)

- 415 V, 3 Phase, 50 Hz Volt (v)

- Up to 8 mm (varies by material) Millimeter (mm)

- 35 1800 RPM RPM

- Conventional Lathe Machine

- Blue/Grey

Conventional Lathe Machine Trade Information

- 20 Unit Per Month

- 4-5 Days

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

Product Description

conventional lathe machine

Our offered machine is assembled by using premium quality materials and by implementing latest technologies. Our offered machines are use to carry our heavy metal shaping jobs and make sure perfection. Due to its durability, low maintenance and trouble free performance, this Lathe Machine finds huge demand in the market. In addition to this, Lathe Machine is offered to our valuable customers at market leading prices.

All Geared Lathe Machine :

Technical Specification in mm

|

Perticular |

250 |

|

Description |

|

|

Height of Centre(mm) |

250 |

|

Swing Over Bed (mm) |

490 |

|

Swing Over Cross Slide (mm) |

290 |

|

Distance Between Center (mm) |

965mm |

|

Max. Swing in Gap (mm) |

770 |

|

BED |

|

|

Bed Type |

2 V & 2 Flat |

|

Bed Width (mm) |

325 |

|

Length of Gap in Front of Face Plate (mm) |

240 |

|

HEAD STOCK |

|

|

Number of Feeds |

18 |

|

Spindel Speed Range : R.P.M. |

32 TO 1650 |

|

Spindle Bore ( mm) |

55 |

|

Spindle Taper Number |

MT - 4 |

|

FEEDS AND THREADS |

|

|

Number of Feeds |

76 |

|

Range of longitudinal Feeds (mm/Rev) |

0.026 to 0.936 |

|

Range of Cross Feeds (mm/rev) |

0.016 to 0.62 |

|

Number of Threads |

106 |

|

Range of Metric Threads/No. |

0.2 to 7 mm (33) |

|

Range of Inch Threads,No. |

72 to 4 TPI (36) |

|

Range of Module Threads/No. |

0.3 to 3 Module (16) |

|

Range of D.P. Threads/No. |

44 to 8 D.P. (21) |

|

Leed Screw Dia (mm) |

38.1 |

|

Leed Screw Pitch (mm) |

6 mm |

|

SADDLE |

|

|

Cross Slide Dimension (mm) |

460 x 205 |

|

Cross Slide Travel (mm) |

200 |

|

Compound Slide Traverse (mm) |

150 |

|

TAIL STOCK |

|

|

Spindle Dia (mm) |

63.5 |

|

Spindle Taper Number |

MT-4 |

|

Spindle Travel |

175 |

|

Lateral Move to Tail Stock (mm) |

5 |

|

MOTOR |

|

|

Main MKotor (Kw.) |

3 |

STANDARD ACCESSORIES

Four Position Tool Post, Toolpost Spanners, Center Adopter, 2 Nos. MT-3 Dead Centers, Electric Motor with Electrical Controls, Thread Dial Indicator, Camlock operating Handle, Chip Tray.

EXTRA ACCESSORIES

- Collet attachment

- Machine Lamp

- Quick change Tool Post

- Collet ( 1 mm to 25 mm ) each collet cost

- Chuck Flange 8"

- Coolant Pump & Fitting

- Collet ( 4 mm to 40 mm ) each collet cost

- Chuck Flange 10"

- Carrier Plate

- Taper Turning Attachment

- Face plate ( 350 mm Dia )

- Extra Center Height 2"

- Rear Tool Post

- Follow Rest

- Digital Read out System (DRO)

- Mechanical Brake

- Steady Rest

All The above specifications are approximate and subject to change without prior notice as improvements are made from time to time.- The Description " standard accessories / features " confirms to its list not the photo of models shown in the catalog.

Heavy Duty Lathe Machine :

Technical Specification in mm

|

Parts |

Specification |

Heavy-1 |

Heavy-2 |

Heavy-3 |

Heavy-4 |

Heavy-5 |

|

Bed |

Length of Bed |

5 6" (1708) |

7 (2135) |

9 (2745) |

10 (3050) |

12 (3650) |

|

Capacity |

Height of Centre |

10" (254) |

10" (254) |

10" (254) |

10" (254) |

10" (254) |

|

Main Spindle |

Spindle Nose |

76 x 6 TPI |

76 x 6 TPI |

76 x 6 TPI |

76 x 6 TPI |

76 x 6 TPI |

|

Tail Stock Spindle |

Diameter |

2.1/2" (63.5) |

2.1/2" (63.5) |

2.1/2" (63.5) |

2.1/2" (63.5) |

2.1/2" (63.5) |

|

Speed |

No. of speed |

8 |

8 |

8 |

8 |

8 |

|

Threads |

Metric thread |

1 to 6 |

1 to 6 |

1 to 6 |

1 to 6 |

1 to 6 |

|

Electric |

Motor Power |

3 H.P III |

3 H.P III |

3 H.P III |

3 H.P III |

3 H.P III |

|

Drive |

Counter to spindle |

C 72 x 2 no. |

C 72 x 2 no. |

C 72x 2 no. |

C 72x 2 no. |

C 72x 2 no. |

|

General |

space (L x W x H) |

81 x 45 x 50 |

99 x 45 x 50 |

122 x 45x50 |

134 x 45x 50 |

158 x 45 x 50 |

Technical Specification in mm

|

Parts |

Specification |

Medium 4 6" |

Medium 5 3" |

Medium 6 |

|

Bed |

Length of Bed |

4 6" (1370mm) |

5 3 "(1600mm) |

6 (1830mm) |

|

Capacity |

Height of Centre |

8II (215mm) |

8II (215mm) |

8II (215mm) |

|

Main Spindle |

Spindle Nose |

75mm x 6 TPI |

75mm x 6 TPI |

75mm x 6 TPI |

|

Tail Stock Spindle |

Diameter |

2" (50.8mm) |

2" (50.8mm) |

2" (50.8mm) |

|

Speed |

No. of speed |

6 |

6 |

6 |

|

Threads |

Metric thread |

M 1 to 6 |

M 1 to 6 |

M 1 to 6 |

|

Electric |

Motor Power |

2 H.P III |

2 H.P III |

2 H.P III |

|

Drive |

Counter to spindle |

B - 48 x 2 no. |

B - 48 x 2 no. |

B - 48 x 2 no. |

|

General |

Floor space (L x W x H) |

65" x 39" x 55" |

76" x 39" x 58" |

84" x 39" x 55" |

STANDARD ACCESSORIES

Chuck Plate, Face Plate, Change Gear Set, Steady Rest, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note: Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost.

As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Meduim Duty Lathe Machine :

STANDARD ACCESSORIES

Chuck Plate, Change Gear Set, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note :

Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost.

As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Light Duty Lathe Machine :

Technical Specification in mm

|

Parts |

Specification |

Light 4II |

|

Bed |

Length of Bed |

4II (1370mm) |

|

Capacity |

Height of Centre |

6II" (165mm) |

|

Main Spindle |

Spindle Nose |

60mm x 8 TPI |

|

Tail Stock Spindle |

Diameter |

1 5/8" (40mm) |

|

Speed |

No. of speed |

8 |

|

Threads |

Metric thread |

M 1 to 6 |

|

Electric |

Motor Power |

1 H.P III |

|

Drive |

Counter to spindle |

B -42 |

|

General |

Floor space (L x W x H) |

65" x 28" x 55" |

STANDARD ACCESSORIES

Chuck Plate, Change Gear Set, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note :

Robust Structure for Industrial Demands

Built on a cast iron frame, the lathe offers durability and stability during metalworking operations. Its precision spindle and hardened, ground bed ensure consistent accuracy and longevity, making it suitable for busy workshops and small-scale manufacturing units.

Versatile Machining Capabilities

The machine accommodates a wide range of tasks, including turning, facing, thread cutting, and drilling. With a 3-jaw chuck size of 200 mm and a main motor power of 2 HP, it is engineered to handle workpieces up to 1000 mm in length, with cross slide travel extending up to 250 mm, and cutting thickness up to 8 mm depending on the material.

Easy Manual Operation

This conventional (non-CNC) lathe is controlled manually, making it reliable and straightforward for operators. It is equipped with essential accessories such as change gears, centers, and a coolant system to optimize workflow and enhance process safety.

Quality Finish and Precision

Achieve standard surface finishes (Ra 3.2 m) and precise cuts, supported by up to 12 spindle speed steps for flexible machining. The design prioritizes both accuracy and repeatability, ensuring high-quality results even in demanding production environments.

FAQs of Conventional Lathe Machine:

Q: How do I operate the Conventional Lathe Machine for metal turning?

A: To operate the lathe, securely mount your metal workpiece between the centers or in the 3-jaw chuck, set the appropriate spindle speed (35 1800 RPM) based on material, and manually use feed and cross-slide controls to perform turning operations. Always follow safety guidelines, use coolant if needed, and select correct tooling for optimal results.Q: What types of applications is this lathe suitable for?

A: This conventional lathe machine is ideal for metal turning, thread cutting, facing, and drilling tasks. Its medium-heavy duty capacity supports machining of parts up to 1000 mm in length and a swing diameter of 410 mm, making it suitable for workshops, repair centers, and small manufacturing units.Q: When should the change gears and coolant system be used?

A: Change gears are necessary when adjusting for various thread cutting pitches or feed rates, typically during setup of threading operations. The coolant system should be used when machining harder materials or performing longer cuts to dissipate heat, preserve tool life, and maintain a superior surface finish.Q: Where can this lathe machine be installed?

A: The lathe is designed for industrial environments such as workshops, manufacturing facilities, and tool rooms. Its dimensions (2650 x 900 x 1250 mm) and power requirement (415 V, 3 Phase) require adequate floor space and electrical provisions typically found in industrial settings.Q: What is the process for cutting threads on this lathe?

A: Thread cutting involves mounting the workpiece, selecting the correct change gears to match your thread pitch, setting the spindle speed, and using the leadscrew (35 mm diameter) to synchronize cutting tool movement. Manual engagement of controls guides the tool along the workpiece to form accurate threads with desired specifications.Q: What are the benefits of using a conventional lathe over CNC models?

A: Conventional lathes provide hands-on manual control, offering ease of use for single-piece or prototype work, flexibility for various tasks, and lower operational costs. They are ideal for workshops that value adaptability and direct operator involvement in the machining process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Lathe Machines' category

|

UMA ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese