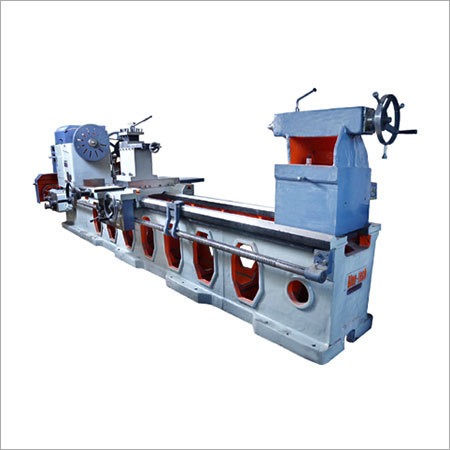

Extra Heavy Duty Lathe Machine

Extra Heavy Duty Lathe Machine Specification

- Product Type

- Extra Heavy Duty Lathe Machine

- Material

- Cast Iron Body, Alloy Steel Gears

- Automatic Grade

- Manual

- Control System

- Manual Lever & Gear System

- Feature

- Other

- Color

- Standard Machine Grey

- Spindle Bore

- 100 mm

- Tailstock Quill Diameter

- 90 mm

- Gear Material

- Alloy Steel, hardened & ground

- Tailstock Travel

- 180 mm

- Application

- Turning, facing, threading of heavy shafts and rolls

- Number of Feeds

- 36

- Lubrication System

- Centralized lubrication

- Power of Main Motor

- 5 HP / 7.5 HP

- Surface Finish

- Fine precision finish

- Spindle Nose

- C.I. accurate nose, A2-8

- Working Accuracy

- Within 0.01 mm

- Distance Between Centers

- 2000 mm / 2500 mm / 3000 mm

- Chuck Size

- 400 mm diameter

- Coolant System

- Provided

- Headstock Type

- Heavy duty, precision gear box type

- Thread Range

- 2-112 mm pitch

- Bed Length

- 2500 mm / 3000 mm / 4000 mm (model dependant)

Extra Heavy Duty Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 4-5 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Extra Heavy Duty Lathe Machine

Extra Heavy Duty Lathe Machine

Features:

- Robust construction

- Flawless finish

- Corrosion resistance

- High performance

Technical Specification

STANDARD ACCESSORIES

Chuck Plate, Face Plate, Change Gear Set, Steady Rest, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note: Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost. As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Engineered for Heavy-Duty Precision

This lathe machine is purpose-built for large-scale, high-precision machining. Its extra rigid bed, precision ground guides, and sturdy tailstock deliver accuracy within 0.01 mm, ensuring superior results on heavyweight workpieces. Used in demanding sectors like metal fabrication and roll manufacturing, its structure absorbs vibrations and maintains stability during sustained operations.

Flexible Performance Across Applications

With a variable cutting speed range of 40-1500 RPM and thread cutting from 2112 mm pitch, this machine is suitable for a wide variety of turning, facing, and threading jobs. The 36 feeds and robust 100 mm spindle bore enable processing of substantial shafts and rolls, making it ideal for manufacturers working with castings, forgings, or large assemblies.

Operator-Friendly Manual Controls

Featuring a manual lever and gear control system, the machine allows skilled operators to fine-tune settings for each task. Centralized lubrication and coolant systems simplify maintenance, while the heavy-duty design enhances operator safety and minimises downtime.

FAQs of Extra Heavy Duty Lathe Machine:

Q: How is the Extra Heavy Duty Lathe Machine typically used in industrial environments?

A: This lathe machine is primarily utilized for turning, facing, and threading heavy shafts and rolls. Its robust construction and high capacity make it suitable for large workpieces up to 10 tons, commonly found in metal fabrication workshops, roll manufacturing plants, and general heavy engineering industries.Q: What materials and components are used in the manufacturing of this lathe?

A: The lathe is constructed with a cast iron body for optimal rigidity and vibration damping. The gears are made from hardened and ground alloy steel, ensuring longevity and smooth performance under heavy loads.Q: When should operators consider using this model over lighter lathe machines?

A: Operators should choose this extra heavy duty model when working with oversized workpieces, high-precision requirements (within 0.01 mm), or when repetitive heavy-duty turning, facing, or threading operations are necessary. Its capacity, size, and features are best utilized in scenarios where lighter machines would lack the required stability and strength.Q: Where is this lathe machine most commonly installed or utilized?

A: This lathe is commonly installed in heavy engineering workshops, steel plants, roll manufacturing units, and large-scale fabrication shops across India. Its design caters to environments requiring consistent machining of large or dense components.Q: What processes are supported by the included features such as the centralized lubrication and coolant systems?

A: The centralized lubrication system reduces friction and wear on moving parts, extending the machines lifespan and maintaining precision accuracy. The coolant system helps regulate temperature during cutting, which prevents tool and workpiece overheating, ensuring a fine surface finish.Q: How does the manual lever & gear control system benefit machine operators?

A: The manual control system allows skilled operators to precisely adjust spindle speed, feed rate, and gear selection according to task requirements. This flexibility ensures optimal machining results for varying materials, sizes, and complexity of operations.Q: What advantages does the extra rigid bed and heavy-duty tailstock bring to machining operations?

A: The extra rigid bed minimizes vibration and deflection during cutting, helping maintain tight tolerances and surface finish. The heavy-duty tailstock supports long or heavy workpieces, enhancing overall stability and achieving consistent, high-accuracy machining.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heavy Duty Lathe Machines Category

Extra Heavy Duty Lathe Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : SS

Control System : PLC Control

Automatic Heavy Duty Lathe Machine

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Cast Iron, Mild Steel

Control System : Other, Push Button/Lever Operated

|

UMA ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry