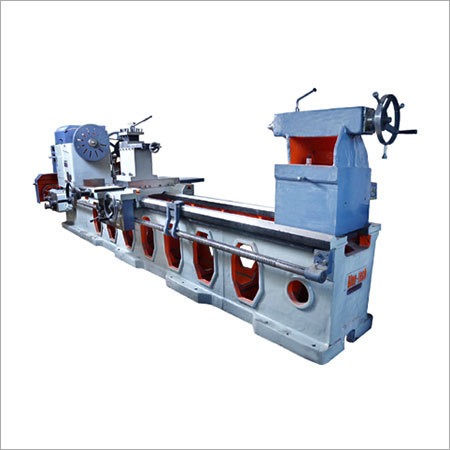

Automatic Heavy Duty Lathe Machine

Price 175000 INR/ Piece

Automatic Heavy Duty Lathe Machine Specification

- Product Type

- Automatic Heavy Duty Lathe Machine

- Material

- Cast Iron, Mild Steel

- Automatic Grade

- Automatic

- Control System

- Push Button/Lever Operated

- Feature

- Other

- Color

- Industrial Grey/Green

- Lead Screw Diameter

- 40 mm

- Surface Finish

- Powder Coated/Enamel Painted

- Distance Between Centers

- 1500 mm

- Application

- Metal Turning, Facing, Thread Cutting

- Chuck Size

- 400 mm

- Number of Gear Speeds

- 12 (Standard)

- Tailstock Quill Diameter

- 75 mm

- Main Motor Power

- 5 HP (3.7 kW)

- Spindle Bore

- 80 mm

- Power Source

- Three Phase Electric

- Bed Width

- 450 mm

Automatic Heavy Duty Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 4-5 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Automatic Heavy Duty Lathe Machine

Features of Automatic Heavy Duty Lathe Machine :

- Robust construction

- Flawless finish

- Corrosion resistance

- High performance

Products Special Features of Lathe MACHINE:

Face plate, Steady rest, Follow rest, Rapid traverse of main saddle, Chuck flange, Independent dog chuck, Elec. Coolant pump with tank & fittings, Taper turning attachment, Machine Lamp with control transformer

Technical Specification

STANDARD ACCESSORIES

Chuck Plate, Face Plate, Change Gear Set, Steady Rest, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note: Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost. As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Precision Engineering for Demanding Applications

This heavy-duty lathe machine is designed to support high-precision operations needed in metal turning, facing, and thread cutting. Its precision-ground bed and 12 standard gear speeds allow accurate and repeatable outcomes, even in tough working conditions. Enhanced rigidity ensures vibration-free machining for consistent and flawless results every time.

Rugged Construction and Versatile Capacity

Crafted from robust cast iron and mild steel, the lathe stands out for its durability and overload protection during continuous industrial use. The machine accommodates workpieces up to 1500 mm in length and a maximum swing of 800 mm, making it ideal for a range of heavy-duty tasks across industries. Its industrial-grade grey or green finish further adds to its resilience.

User-Friendly Controls and Safe Operation

Equipped with straightforward push-button and lever controls, the machine allows for intuitive and efficient operation. Its automatic functions minimize manual intervention, enhancing both productivity and safety for operators. The three-phase electric system and 5 HP motor ensure reliable performance even during prolonged use.

FAQs of Automatic Heavy Duty Lathe Machine:

Q: How does the automatic heavy duty lathe machine enhance metalworking efficiency?

A: This lathe features automatic controls, a high main motor power of 5 HP, and 12 gear speeds, which together enable efficient and consistent metal turning, facing, and thread cutting. The variable speed range from 40 to 2000 RPM allows users to select ideal cutting conditions for various materials, improving productivity and finish quality.Q: What types of workpieces can be machined, and what is the maximum capacity?

A: The machine can handle workpieces up to 1500 mm in length with a swing diameter of up to 800 mm and a cutting thickness of 30 mm. This makes it suitable for large, heavy-duty components in applications such as industrial parts, shafts, and cylinders.Q: When should I consider using a heavy-duty lathe like this over a standard model?

A: You should use this machine when your application requires processing large, heavy, or hard materials that demand increased rigidity and power. Its heavy-duty design, larger spindle bore, and precision-ground bed make it suitable for high-volume or industrial-scale metal fabrication.Q: Where is the automatic heavy duty lathe machine most commonly installed?

A: This machine is typically installed in metal fabrication plants, machining workshops, tool rooms, and manufacturing units that require consistent, reliable operations. It is well-suited for environments that handle both single-piece and batch production.Q: What is the process of operating this lathe machine?

A: Operators secure the workpiece in the large 400 mm chuck, set the required speed using the lever or push-button controls, and begin machining. The automatic features minimize manual adjustments, while the variable speed and precise controls ensure smooth operation and accurate results.Q: What safety mechanisms are integrated into the lathe machine?

A: The machine is constructed from durable materials with a fully enclosed drive system, and the manual push button/lever control allows for immediate machine stoppage if needed. The heavy-duty bed and precision gears further ensure stable and safe operation even under continuous loads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heavy Duty Lathe Machines Category

Extra Heavy Duty Lathe Machine

Price 450000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : PLC Control

Automatic Grade : Automatic

Material : SS

Extra Heavy Duty Lathe Machine

Price 950000 INR

Minimum Order Quantity : 1 Unit

Control System : Other, Manual Lever & Gear System

Automatic Grade : Other, Manual

Material : Cast Iron Body, Alloy Steel Gears

|

UMA ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry