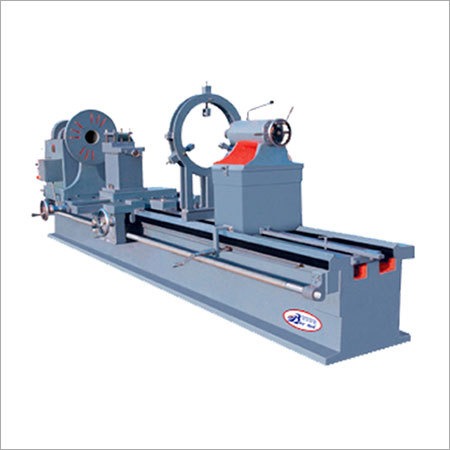

Automatic Lathe Machine

Price 950000 INR/ Piece

Automatic Lathe Machine Specification

- Product Type

- Automatic Lathe Machine

- Material

- Alloy Steel

- Automatic Grade

- Automatic

- Control System

- Mechanical Cam Operated

- Feature

- Other

- Color

- Blue-Grey

- Spindle Speed

- 900-3800 rpm

- Number of Tool Posts

- 6

- Supported Workpiece Length

- Up to 600 mm

- Maintenance

- Low Maintenance Designed

- Operating Temperature

- 5C - 45C

- Coolant System

- Integrated

- Safety Features

- Overload Protection, Enclosure Guards

- Lubrication System

- Automatic

- Installation

- Onsite Available

- Noise Level

- <72 dB

- Surface Finish Quality

- Ra 0.8-1.6

- Chuck Type

- Self-Centering

- Power Supply

- 3 Phase 50 Hz

- Drive Motor Power

- 2.2 kW

Automatic Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 20 Pieces Per Month

- Delivery Time

- 4-5 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Automatic Lathe Machine

Lathe Machine :-

We are proud to introduce ourselves as a well known manufacturer, exporter and supplier of Lathe Machine. Our offered machine is assembled by using premium quality materials and by implementing latest technologies. Our offered machines are use to carry our heavy metal shaping jobs and make sure perfection. Due to its durability, low maintenance and trouble free performance, this Lathe Machine finds huge demand in the market. In addition to this, Lathe Machine is offered to our valuable customers at market leading prices.

Features:

- Sturdy construction

- Perfect finish

- Longer service life

- Noise-free operations

All Geared Lathe Machine :

Technical Specification in mm

STANDARD ACCESSORIES Four Position Tool Post, Toolpost Spanners, Center Adopter, 2 Nos. MT-3 Dead Centers, Electric Motor with Electrical Controls, Thread Dial Indicator, Camlock operating Handle, Chip Tray

EXTRA ACCESSORIES

- Collet attachment

- Machine Lamp

- Quick change Tool Post

- Collet ( 1 mm to 25 mm ) each collet cost

- Chuck Flange 8"

- Coolant Pump & Fitting

- Collet ( 4 mm to 40 mm ) each collet cost

- Chuck Flange 10"

- Carrier Plate

- Taper Turning Attachment

- Face plate ( 350 mm Dia )

- Extra Center Height 2"

- Rear Tool Post

- Follow Rest

- Digital Read out System (DRO)

- Mechanical Brake

- Steady Rest

Note :

All The above specifications are approximate and subject to change without prior notice as improvements are made from time to time.

The Description " standard accessories / features " confirms to its list not the photo of models shown in the catalog.

Heavy Duty Lathe Machine :

Technical Specification in mm

Technical Specification in mm

STANDARD ACCESSORIES

Chuck Plate, Face Plate, Change Gear Set, Steady Rest, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note:Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost.

As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Meduim Duty Lathe Machine :

STANDARD ACCESSORIES Chuck Plate, Change Gear Set, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note :

- Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost.

- As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Light Duty Lathe Machine :

Technical Specification in mm

STANDARD ACCESSORIES Chuck Plate, Change Gear Set, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note :

Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost. As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Precision and Productivity

This automatic lathe machine is tailored for high-precision turning, capable of producing up to 800 pieces per hour. Its stable drive, advanced coolant, and automatic lubrication systems support continuous and reliable operation, minimizing downtime. The blue-grey finished equipment integrates seamlessly into modern workshops and is suitable for a range of alloy steel components. With low noise emissions (<72 dB), it consistently delivers superior surface finishes for varied industrial applications.

Easy Installation and Maintenance

Onsite installation is available across India, ensuring the equipment is set up and functioning optimally from day one. Built-in features, like automatic lubricating and integrated coolant systems, drastically reduce routine maintenance tasks and extend the life of critical components. The robust design further guarantees durability, while its mechanical cam-operated control ensures reliability without complex CNC interventions.

FAQs of Automatic Lathe Machine:

Q: How is the Automatic Lathe Machine installed and what support is provided?

A: Installation services are offered onsite across India to ensure the machine is correctly set up. Our expert technicians handle assembly, initial calibration, and basic operator training for a seamless start-up process.Q: What materials and workpiece sizes can this lathe machine handle?

A: The machine is designed primarily for alloy steel but accommodates other compatible materials. It supports workpieces up to 600 mm in length, a maximum swing diameter of 320 mm, cutting thickness from 1 to 60 mm, and delivers high precision for a variety of turning needs.Q: When should regular maintenance be performed on this lathe?

A: Thanks to the automatic lubrication and integrated coolant system, maintenance requirements are minimal. However, it is recommended to inspect key components every few months and follow suggested manufacturer guidelines to ensure continuous, smooth operation.Q: What is the process for utilizing multiple tool posts on this automatic lathe?

A: With its 6 tool posts, the lathe allows for rapid tool changes during operation. The mechanical cam-operated system facilitates seamless transitions, supporting complex turning sequences for higher productivity without manual adjustments between each process.Q: Where can this automatic lathe operate, and what power supply does it require?

A: Suitable for factory floors and machine shops, the lathe operates in environments with temperatures between 5C and 45C. It requires a three-phase, 415V, 50Hz power supply for optimal and safe performance.Q: What usage benefits does this lathe machine offer compared to manual models?

A: This automatic lathe excels in delivering precision (Ra 0.8-1.6 surface finish), high throughput (up to 800 pieces/hour), and enhanced safety. Features like overload protection, enclosure guards, and self-centering chucks minimize risks and errors compared to traditional manual machines.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machines Category

Industrial Heavy Duty Lathe Machine

Price 225000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : SS

Control System : PLC Control

Feature : High Performance

Industrial Lathe Machine

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : SS

Control System : PLC Control

Automatic Lathe Machine, 1000-2000 rpm, 500-750 mm

Price 250000 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : MS

Control System : Frequency Speed Control

Feature : Simple Control, High Performance, ECO Friendly, Lower Energy Consumption

Automatic Lathe Machines

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : Automatic

Material : Highspeed steel, Cast Iron body

Control System : Other, Cam automatic

Feature : Other

|

UMA ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry