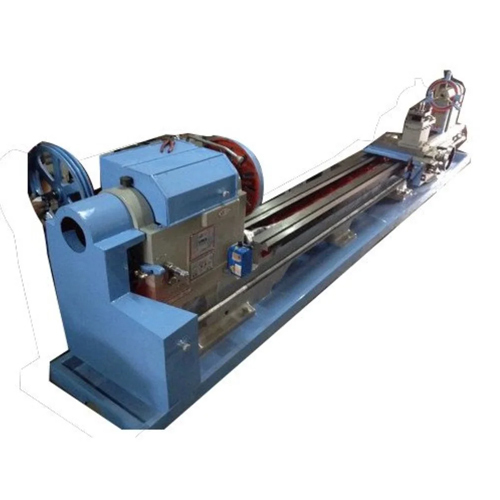

Metal Lathe Machine

Price 110000 INR/ Unit

Metal Lathe Machine Specification

- Product Type

- Manual Metal Lathe Machine

- Material

- Cast Iron Body, Hardened Steel Gears

- Cutting Thickness

- Up to 20 mm Millimeter (mm)

- Cutting Speed

- 40 - 2000 RPM RPM

- Automatic Grade

- Semi-Automatic

- Control System

- Manual with Gear Box

- Max. Swing Diameter

- 400 mm Millimeter (mm)

- Voltage

- 415 V Volt (v)

- Weight (kg)

- 970 kg Kilograms (kg)

- Dimension (L*W*H)

- 1950 mm x 750 mm x 1100 mm Millimeter (mm)

- Capacity

- 1.5 kW motor, medium-duty applications Pcs/hr

- Feature

- Other

- Color

- Blue & Silver

- Chuck Size

- 200 mm (3-jaw) included

- Number of Spindle Speeds

- 8

- Motor Power

- 1.5 kW (2 HP), 3 Phase

- Spindle Bore

- 52 mm

- Center Height

- 205 mm

- Feed Range

- 0.05 1.5 mm/rev

- Distance Between Centers

- 1000 mm

- Bed Width

- 230 mm

- Thread Range

- 0.5 7 mm (Metric), 4 60 TPI (Inch)

- Tailstock Quill Travel

- 130 mm

- Surface Finish

- Roughness < 3.2 m

- Coolant System

- Fitted with pump

- Noise Level

- 80 dB(A)

Metal Lathe Machine Trade Information

- Minimum Order Quantity

- 01 Unit

- Payment Terms

- Cash on Delivery (COD), Cash in Advance (CID)

- Supply Ability

- 20 Units Per Month

- Delivery Time

- 4-5 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Metal Lathe Machine

metal lathe machine

- One piece lathe bed casting ensures better rigidity

- Head stock gears are of special alloy steel

- Head stock spindle is ground and runs in one anti friction taper roller bearings and one ball bearings in front wall of head stock and one taper roller bearing in rear side wall of head stock.

All Geared Lathe Machine :

Technical Specification in mm

STANDARD ACCESSORIES Four Position Tool Post, Toolpost Spanners, Center Adopter, 2 Nos. MT-3 Dead Centers, Electric Motor with Electrical Controls, Thread Dial Indicator, Camlock operating Handle, Chip Tray

EXTRA ACCESSORIES

- Collet attachment

- Machine Lamp

- Quick change Tool Post

- Collet ( 1 mm to 25 mm ) each collet cost

- Chuck Flange 8"

- Coolant Pump & Fitting

- Collet ( 4 mm to 40 mm ) each collet cost

- Chuck Flange 10"

- Carrier Plate

- Taper Turning Attachment

- Face plate ( 350 mm Dia )

- Extra Center Height 2"

- Rear Tool Post

- Follow Rest

- Digital Read out System (DRO)

- Mechanical Brake

- Steady Rest

Note :

All The above specifications are approximate and subject to change without prior notice as improvements are made from time to time.

The Description " standard accessories / features " confirms to its list not the photo of models shown in the catalog.

Heavy Duty Lathe Machine :

Technical Specification in mm

Technical Specification in mm

STANDARD ACCESSORIES

Chuck Plate, Face Plate, Change Gear Set, Steady Rest, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note:Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost.

As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Meduim Duty Lathe Machine :

STANDARD ACCESSORIES Chuck Plate, Change Gear Set, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note :

- Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost.

- As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Light Duty Lathe Machine :

Technical Specification in mm

STANDARD ACCESSORIES Chuck Plate, Change Gear Set, Tool Post Key, Dead Centers, Center Adaptor, Motor Pully.

Note :

Any Altertoin in respect of ourstd. specifiction will be welcomed at extra cost. As improvements are constantly made in our machine the above specification, dimension and weight are subject to change without notice & are not binding on us.

Enhanced Durability and Precision

Constructed with a cast iron body and hardened steel gears, this lathe assures high rigidity and accuracy. The precision-ground bed and oil bath gear system minimize wear and enhance long-term reliability, making it ideal for both routine and intricate metalworking tasks.

Comprehensive Machining Capacity

With a swing diameter of 400 mm and a distance of 1000 mm between centers, the lathe provides substantial work space for medium-sized components. Its metric thread range of 0.5 7 mm and inch range of 4 60 TPI enable versatile threading operations for a variety of applications.

User-Friendly Manual Control

The manual gear box system grants operators clear control over speeds and feed rates, spanning 40 2000 RPM and 0.05 1.5 mm/rev, respectively. A semi-automatic grade ensures ease of use while maintaining operator engagement during all machining stages.

FAQs of Metal Lathe Machine:

Q: How does the coolant system benefit the metal lathes operation?

A: The lathe is supplied with a fitted coolant pump, which helps dissipate heat during machining, reduces tool wear, and ensures superior surface finishes.Q: What types of projects can be performed with this metal lathe?

A: This machine is well-suited for turning, facing, threading, and cutting applications on medium-duty components, with its workpiece capacity of up to 1000 mm between centers and a maximum swing of 400 mm.Q: When should I select this manual lathe over a CNC model?

A: This manual gear box lathe is ideal whenever flexibility, hands-on control, and cost-effective machining for small to medium batch runs are required, especially where CNC programming is unnecessary.Q: Where is this metal lathe typically installed and used?

A: Due to its sturdy construction and moderate footprint, it is commonly installed in manufacturing workshops, tool rooms, and educational settings for precision metalworking.Q: What is the process for changing spindle speeds or feed rates?

A: Operators can select from 8 spindle speeds and a wide feed range by manually adjusting the gear levers on the gearbox, allowing for quick adaptation to specific work requirements.Q: How is high surface finish achieved on this lathe machine?

A: With a precision-ground bed, oil bath gears, and accurately aligned components, this lathe delivers a roughness value of less than 3.2 m, ensuring smooth-machined surfaces.Q: What advantages does the 3-jaw chuck offer for users?

A: The included 200 mm 3-jaw chuck securely grips cylindrical workpieces, facilitating quick and precise centeringideal for repetitive or high-accuracy tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Lathe Machines Category

Gap Bed Lathe Machine, Swing Over Bed 360 Mm

Price 250000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Horizontal

Material : MS

Feature : Simple Control, High Performance, ECO Friendly, Lower Energy Consumption

Control System : Human Machine Interface

indian lathe machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 Piece

Product Type : Other, Manual Lathe Machine

Material : Cast Iron, Steel

Feature : Other

Control System : Other, Manual Mechanical Control

Automatic Lathe Machines

Price 175000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Other, Automatic Lathe Machine

Material : Highspeed steel, Cast Iron body

Feature : Other

Control System : Other, Cam automatic

Boring Lathe Machine

Price 450000 INR

Minimum Order Quantity : 1 Piece

Product Type : Other, Horizontal Boring Lathe Machine

Material : Cast Iron Body

Feature : Other

Control System : Other, Manual Control

|

UMA ENTERPRISE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry